Encoders are divided into two classes, magnetic and optical. The terms magnetic and optical refer to the type of mechanics the encoder uses.

Some Cut-to-length timber harvesters are sold to the logger with an inferior encoder.

The inferior encoder is built using optical technology. (For example view the image to the left)

The Logging Duty Encoder is built with magnetic technology (click link to learn more).

Only magnetic encoders are suited to handle the unforgiving conditions that occur in the center of timber harvesters.

Do you have a box of broken encoders?

Learn about our broken encoder buy back program. LoggingEncoders.com will buy your broken encoder!

Visit our “WE BUY BROKEN ENCODERS” page to learn more!

Are You Destroying Encoders?

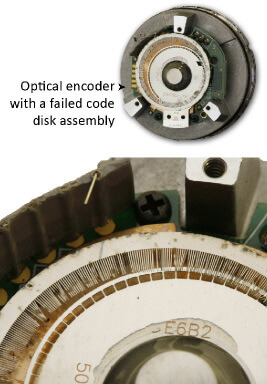

Optical encoders depend on an optical eye which detects variations in an opaque disk. The disk spins relative to the rotation of the encoder’s shaft.

The Magnetic Solution

Magnetic encoders do not require any fragile mechanics to operate. Their sensing depends on solid state microchips which contain no moving parts.

Visit the Design page to learn more about the magnetic advantage and how changing your class of encoder from optical to magnetic can help guarantee the maximum possible up-time.